When it comes to fluid control in various industries, solenoid valves have gained notable popularity. These electromechanical devices offer precise control over the flow of fluids, making them an essential component in applications ranging from manufacturing to healthcare.

However, determining whether solenoid valves are worth the investment can be critical for many businesses. This article will explore the benefits of using solenoid valves in diverse industries.

Rapid Response Time

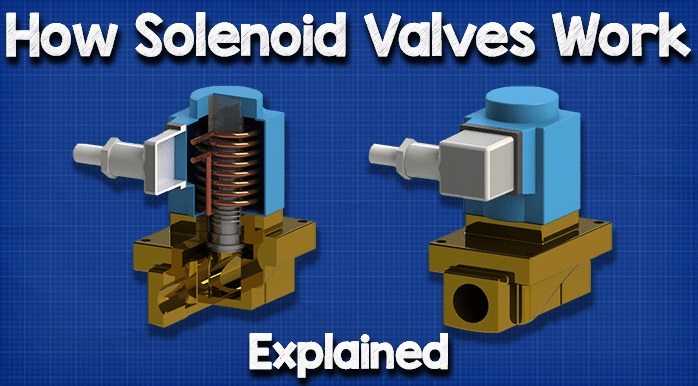

Solenoid valves offer a swift and responsive solution for controlling the flow of fluids or gases in diverse industrial applications. The key to their rapid response lies in the electromagnetic mechanism they employ.

When an electrical current is applied, the solenoid coil generates a magnetic field, causing the valve to open or close almost instantly. This quick response time is crucial in scenarios requiring precise and immediate fluid flow control, enhancing overall system efficiency.

High Precision and Accuracy

Their on-off control mechanism allows for accurate fluid or gas passage adjustment, ensuring that the desired amount is delivered precisely when needed. This precision is vital in applications where specific quantities of substances must be distributed or where maintaining exact pressure levels is crucial.

Industries such as pharmaceuticals, food processing, and laboratories benefit from the accuracy of solenoid valves, contributing to the reliability and consistency of their processes.

Versatility in Controlling Various Fluids

These valves are versatile in handling different fluids, including liquids and gases. Their adaptable design allows them to control the flow of substances with varying viscosities, temperatures, and chemical properties.

This versatility makes solenoid valves suitable for various industries, from water treatment and oil refineries to pharmaceuticals and food processing, where different fluids must be precisely regulated.

Compact Design and Easy Installation

The small size and lightweight nature of these valves make them easy to install in various systems, even when space is limited. Their simplicity and ease of installation contribute to cost-effective and efficient solutions for fluid control. This is especially beneficial in industries where optimizing space and minimizing installation complexities are priorities.

Wide Range of Types and Configurations

Solenoid valves come in diverse types and configurations to meet specific industry requirements. Whether it’s a direct-acting, pilot-operated, or diaphragm valve, the variety allows for tailored solutions in different applications.

Additionally, solenoid valves can be configured for specific functions such as on-off control, proportional control, or even three-way and four-way configurations. This adaptability ensures that industries can choose the right solenoid valve type to suit their unique operational needs.

Remote Operation and Control

In certain industries, especially those dealing with hazardous materials or harsh environments, controlling valves remotely enhances safety. Operators can manage critical processes from a safe distance, minimizing exposure to potential risks.

Additionally, remote accessibility facilitates control in hard-to-reach or confined spaces, allowing for efficient operation without needing direct physical presence.

Enjoy the Worthiness of Solenoid Valves

Whether you seek cost-effective solutions, energy efficiency, or compatibility with automation systems, solenoid valves offer a range of benefits that cater to diverse requirements.

As you explore the worthiness of solenoid valves, consider consulting with experts like PCI Pro to ensure you choose the right valve type and configuration for your specific needs. Embrace the efficiency, reliability, and precision solenoid valves bring to your industrial processes.