In optical engineering, expertise in custom optics is vital across various sectors, from cutting-edge tools to advanced consumer gadgets. Precision polish is a critical factor impacting the effectiveness and quality of these optical elements. Comprehending the intricacies of custom optics and the importance of precision polish can provide insight into how optical excellence is attained and sustained.

The Basics of Customized Optical Technology

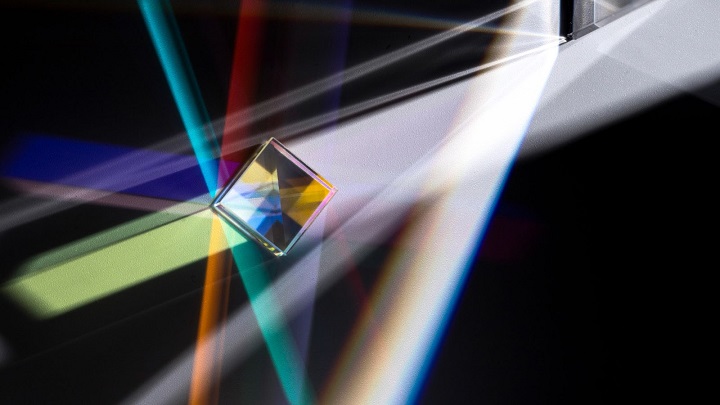

Creating custom solutions entails developing and producing customized optical parts to meet specific needs and standards for performance enhancement in various applications, like lenses and mirrors. The main goal of custom optics is to control light in specific ways to create certain outcomes like sharpened focus or enhanced image quality. This crucial aspect highlights the significance of precision polishing in this field.

The Importance Of Perfecting The Finer Details

Refining surfaces to achieve top-notch clarity and accuracy is known as precision polishing, a crucial process that directly impacts the optical performance of the component.

Even tiny flaws or inconsistencies can impact how light travels. By polishing with precision, the surface can meet the necessary standards, thus reducing distortions and enhancing overall optical functionality.

Blurriness or irregularities in the picture can be due to deviations from the optical path, known as aberrations; some typical examples include spherical aberration and chromatic aberration, among others, like astigmatism. By polishing with precision techniques, these defects can be reduced significantly as it ensures that the optical surfaces meet strict standards in shape and finish. This fine-tuning ultimately enables the device to produce crisp and undistorted images.

Improving the Passage of Light

The quality of how light passes through is greatly affected by how smoothly its surface is polished out. A polished surface helps minimize light scattering and reflections that usually result in losses and improves the efficiency of transmitting light effectively. This aspect is essential in fields like telescopes and microscopes, where ensuring maximum light transmission is vital in achieving the best performance possible.

Crafting custom optics frequently demands optical features, like specific focal lengths or wavelengths. Custom polish empowers manufacturers to meticulously adjust these features by molding and refining the optical surfaces. This degree of precision enables the production of parts that adhere to requirements and deliver reliable performance across various environments.

The Art Of Fine Polishing

The meticulous polishing procedure includes steps that all play a crucial role in shaping the ultimate quality of the optical component.

Lets get started with the step of shaping up the project:

- The first step involves shaping the surface initially by removing significant material to approximate the desired form using grinding techniques.

- Following the shaping process is a more detailed polishing phase to enhance the surface quality further. This step involves using finer materials and specialized polishing compounds to create a smoother surface and eliminate any remaining flaws. The objective is to attain a level of surface precision and smoothness.

- After finishing the polishing process, the component is thoroughly inspected to confirm it meets all necessary specifications by conducting tests such as measuring surface accuracy and checking for any defects or performance issues.

Refined Methods For Precise Polishing

Improvements in precision polish methods are constantly boosting the quality, with various techniques being employed for this purpose.

Automated polishing systems utilize computer algorithms to oversee the polishing procedure, with accuracy to achieve uniform outcomes and decrease the chances of human errors.

In Conclusion

Achieving excellence in custom optics heavily relies on precision polishing as a critical element for ensuring smooth and flawless optical surfaces that enhance the performance of optical components significantly. With technological advancements driving evolution, precision polishing techniques and tools used in the optics industry are pushing boundaries for improved optical performance and innovation.